M16 rifle

| Rifle, 5.56 mm, M16 | |

|---|---|

From top to bottom: M16A1, M16A2, M4A1, M16A4 |

|

| Type | Assault rifle |

| Place of origin | |

| Service history | |

| In service | 1963–present |

| Used by | See Users |

| Wars | Vietnam War–present |

| Production history | |

| Designer |

|

| Designed | 1957 |

| Manufacturer |

|

| Produced | 1960–present |

| Number built | ~8 million [2] |

| Variants | See Variants |

| Specifications (M16A2) | |

| Weight | 7.8 lb (3.5 kg) (unloaded) 8.79 lb (4.0 kg) (loaded) |

| Length | 39.625 in (1,010 mm) |

| Barrel length | 20 in (508 mm) |

|

|

|

| Cartridge | 5.56x45mm NATO |

| Action | Gas-operated, rotating bolt |

| Rate of fire | 700–950 rounds/min, cyclic depending on model |

| Muzzle velocity | 3110 ft/s (948 m/s) [3] |

| Effective range | 600 yd (550 m) point target (800 m) area target |

| Feed system | Various STANAG magazines |

The M16 (more formally Rifle, Caliber 5.56 mm, M16) is the United States military designation for the AR-15 rifle. Colt purchased the rights to the AR-15 from ArmaLite and currently uses that designation only for semi-automatic versions of the rifle. The M16 rifle fires the 5.56x45mm cartridge and can produce massive wounding and hydrostatic shock effects when the bullet impacts at high velocity and yaws in tissue leading to fragmentation and rapid transfer of energy.[4][5][6]

The M16 entered United States Army service as the M16 and was put into action for jungle warfare in South Vietnam in 1963,[7] becoming the standard U.S. rifle of the Vietnam War by 1969,[8] replacing the M14 rifle in that role. The U.S. Army retained the M14 in CONUS, Europe, and South Korea until 1970. Since the Vietnam War, the M16 rifle family has been the primary infantry rifle of the U.S. military. With its variants, it has been in use by 15 NATO countries, and is the most produced firearm in its caliber.

Contents |

Introduction

The M16 is a lightweight, 5.56 mm, air-cooled, gas-operated, magazine-fed assault rifle, with a rotating bolt, actuated by direct impingement gas operation. The rifle is made of steel, 7075 aluminum alloy, composite plastics and polymer materials.

The U.S. Air Force's rifle, the M16, and the United States Marine Corps and Army rifle, the XM16E1, were the first versions of the M16 rifle fielded. Soon, the U.S. Army standardized the XM16E1 as the M16A1 rifle, an M16 with a forward assist feature requested by the Army. All of the early versions were chambered to fire the M193/M196 cartridge in the semi-automatic and the automatic firing modes. This occurred in the early 1960s, with the Army issuing it in late 1964.[9] Commercial AR-15s were first issued to Special Forces troops in spring of 1964.[10]

The M16A2 rifle entered service in the 1980s, chambered to fire the standard NATO cartridge, the Belgian-designed M855/M856 cartridge.[9] The M16A2 is a select-fire rifle (semi-automatic fire, three-round-burst fire) incorporating design elements requested by the Marine Corps:[9] an adjustable, windage rear-sight; a stock 5/8-inch longer; heavier barrel; case deflector for left-hand shooters; and cylindrical hand guards.[9] The fire mode selector is on the receiver's left side. The M16A2 is still the primary rifle in the U.S. Navy, Coast Guard, Air Force, and still is in heavy use in the Army and Marine Corps.

The M16A3 rifle is an M16A2 rifle with an M16A1's fire control group (semi-automatic fire, automatic fire) used only by the U.S. Navy.

The M16A4 rifle was standard issue for the United States Marine Corps in Operation Iraqi Freedom; it replaced the M16A2 in front line units. In the U.S. Army the M16A2 rifle is being supplemented with two rifle models, the M16A4 and the M4 carbine as the standard issue assault rifle. The M16A4 has a flat-top receiver developed for the M4 carbine, a handguard with four Picatinny rails for mounting a sight, laser, night vision device, forward handgrip, removable handle, or a flashlight.

The M16 rifle is principally manufactured by Colt and Fabrique Nationale de Herstal (under a U.S. military contract since 1988 by FNH-USA; currently in production since 1991, primarily M16A2, A3, and A4), with variants made elsewhere in the world. Versions for the U.S. military have also been made by H & R Firearms[11] General Motors Hydramatic Division[12] and most recently by Sabre Defence.[13] Semi-automatic versions of the AR-15 are popular recreational shooting rifles, with versions manufactured by other small and large manufacturers in the U.S.[14]

History

Summary

The AR-15 was first adopted in 1962 by the United States Air Force, ultimately receiving the designation M16. The U.S. Army began to field the XM16E1 en masse in 1965 with most of them going to the Republic of South Vietnam, and the newly organized & experimental Airmobile Divisions, the 1st Air Cavalry Division in particular. The U.S. Marine Corps in South Vietnam also experimented with the M16 rifle in combat during this period. The XM16E1 was standardized as the M16A1 in 1967. This version remained the primary infantry rifle of U.S. forces in South Vietnam until the end of the war in 1975, and remained with all U.S. military ground forces after it had replaced the M14 service rifle in 1970 in CONUS, Europe (Germany), and South Korea; when it was supplemented by the M16A2. During the early 1980s a roughly standardized load for this ammunition was adopted throughout NATO (see: 5.56x45mm NATO).

The M16A3 is a fully-automatic variant of the M16A2, issued within the United States Navy. The M16A2 is currently being supplemented by the M16A4, which incorporates the flattop receiver unit developed for the M4 carbine, and Picatinny rail system. M16A2s are still in stock with the U.S. Army and Marine Corps, but are used primarily by reserve and National Guard units as well as by the U.S. Air Force.

The M16 rifle design, including variant or modified version of it such as the Armalite/Colt AR-15 series, AAI M15 rifle; AP74; EAC J-15; SGW XM15A; any 22-caliber rimfire variant, including the Mitchell M16A-1/22, Mitchell M16/22, Mitchell CAR-15/22, and AP74 Auto Rifle, is a prohibited and restricted weapon in Canada.[15]

Project SALVO

In 1948, the Army organized the civilian Operations Research Office, mirroring similar operations research organizations in the United Kingdom. One of their first efforts, Project ALCLAD, studied body armor and the conclusion was that they would need to know more about battlefield injuries in order to make reasonable suggestions.[16] Over 3 million battlefield reports from World War I and World War II were analyzed and over the next few years they released a series of reports on their findings.[16]

The conclusion was that most combat takes place at short range. In a highly mobile war, combat teams ran into each other largely by surprise; and the team with the higher firepower tended to win. They also found that the chance of being hit in combat was essentially random; accurate "aiming" made little difference because the targets no longer sat still. The number one predictor of casualties was the total number of bullets fired.[16] Other studies of behavior in battle revealed that many U.S. infantrymen (as many as 2/3) never actually fired their rifles in combat. By contrast, soldiers armed with rapid fire weapons were much more likely to have fired their weapons in battle.[17] These conclusions suggested that infantry should be equipped with a fully-automatic rifle of some sort in order to increase the actual firepower of regular soldiers. It was also clear, however, that such weapons dramatically increased ammunition use and in order for a rifleman to be able to carry enough ammunition for a firefight they would have to carry something much lighter.

Existing rifles met none of these criteria. Although it appeared the new 7.62 mm T44 (precursor to the M14) would increase the rate of fire, its heavy 7.62 mm NATO cartridge made carrying significant quantities of ammunition difficult. Moreover, the length and weight of the weapon made it unsuitable for short range combat situations often found in jungle and urban combat or mechanized warfare, where a smaller and lighter weapon could be brought to bear faster.

These efforts were noticed by Colonel René Studler, U.S. Army Ordnance's Chief of Small Arms Research and Development. Col. Studler asked the Aberdeen Proving Ground to submit a report on the smaller caliber weapons. A team led by Donald Hall, director of program development at Aberdeen, reported that a .22 inch (5.56 mm) round fired at a higher velocity would have performance equal to larger rounds in most combat.[18] With the higher rate of fire possible due to lower recoil it was likely such a weapon would inflict more casualties on the enemy. His team members, notably William C. Davis, Jr. and Gerald A. Gustafson, started development of a series of experimental .22 (5.56 mm) cartridges. In 1955, their request for further funding was denied.

A new study, Project SALVO, was set up to try to find a weapon design suited to real-world combat. Running between 1953 and 1957 in two phases, SALVO eventually suggested that a weapon firing four rounds into a 20-inch (508 mm) area would double the hit probability of existing semi-automatic weapons.

In the second phase, SALVO II, several experimental weapons concepts were tested. Irwin Barr of AAI Corporation introduced a series of flechette weapons, starting with a shotgun shell containing 32 darts and ending with single-round flechette "rifles". Winchester and Springfield Armory offered multi-barrel weapons, while ORO's own design used two .22, .25 or .27 caliber bullets loaded into a single .308 Winchester or .30-06 cartridge.

Eugene Stoner

Meanwhile testing of the 7.62 mm T44 continued, and Fabrique Nationale also submitted their new FN FAL via the American firm Harrington & Richardson as the T48. The T44 was selected as the new battle rifle for the U.S. Army (rechristened the M14) despite a strong showing by the T48.

In 1954, Eugene Stoner of the newly-formed ArmaLite helped develop the 7.62 mm AR-10. Springfield's T44 and similar entries were conventional rifles using wood for the "furniture" and otherwise built entirely of steel using mostly forged and machined parts. ArmaLite was founded specifically to bring the latest in designs and alloys to firearms design, and Stoner felt he could easily beat the other offerings.

The AR-10's receiver was made of forged and milled aluminium alloy instead of steel. The barrel was mated to the receiver by a separate hardened steel extension to which the bolt locked. This allowed a lightweight aluminum receiver to be used while still maintaining a steel-on-steel lockup. The bolt was operated by high-pressure combustion gases taken from a hole in the middle of the barrel directly through a tube above the barrel to a cylinder created in the bolt carrier with the bolt carrier itself acting as a piston. Traditional rifles located this cylinder and piston close to the gas vent. The stock and grips were made of a glass-reinforced plastic shell over a rigid foam plastic core. The muzzle brake was fabricated from titanium. Over Stoner's objections, various experimental composite and 'Sullaloy' aluminum barrels were fitted to some AR-10 prototypes by ArmaLite's president, George Sullivan. The Sullaloy barrel was made entirely of heat-treated aluminum, while the composite barrels used aluminum extruded over a thin stainless steel liner.

Meanwhile the layout of the weapon itself was also somewhat different. Previous designs generally placed the sights directly on the barrel, using a bend in the stock to align the sights at eye level while transferring the recoil down to the shoulder. This meant that the weapon tended to rise when fired making it very difficult to control during fully-automatic fire. The ArmaLite team used a solution previously used on weapons such as the German FG 42 and Johnson light machine gun; they located the barrel in line with the stock, well below eye level, and raised the sights to eye level. The rear sight was built into a carrying handle over the receiver.

Despite being over 2 lb (0.9 kg) lighter than the competition, the AR-10 offered significantly greater accuracy and recoil control. Two prototype rifles were delivered to the U.S. Army's Springfield Armory for testing late in 1956. At this time, the U.S. armed forces were already two years into a service rifle evaluation program, and the AR-10 was a newcomer with respect to older, more fully-developed designs. Over Stoner's continued objections, George Sullivan had insisted that both prototypes be fitted with composite aluminum/steel barrels. Shortly after a composite barrel burst on one prototype in 1957, the AR-10 was rejected. The AR-10 was later produced by a Dutch firm, Artillerie Inrichtingen, and saw limited but successful military service with several foreign nations such as Sudan, Guatemala, and Portugal. Portugal deployed a number of AR-10s for use by its airborne (Caçadores Pára-quedista) battalions, and the rifle saw considerable combat service in Portugal's counter-insurgency campaigns in Angola and Mozambique.[19] Some AR-10 rifles were still in service with airborne forces serving during the withdrawal from Portuguese Timor in 1975.

CONARC

In 1957, a copy of Gustafson's funding request from 1955 found its way into the hands of General Willard G. Wyman, commander of the U.S. Continental Army Command. He immediately put together a team to develop a .22 caliber (5.56 mm) weapon for testing. Their finalized request called for a select-fire weapon of 6 pounds (2.7 kg) when loaded with 20 rounds of ammunition. The bullet had to penetrate a standard U.S. steel helmet, body armor, or a 0.135 inch (3.4 mm) steel plate and retain a velocity in excess of the speed of sound at 500 yards (460 m), while equaling or exceeding the "wounding" ability of the .30 Carbine.[16][20]

Wyman had seen the AR-10 in an earlier demonstration, and impressed by its performance he personally suggested that ArmaLite enter a weapon for testing using a 5.56 mm cartridge designed by Winchester.[16] Their first design, using conventional layout and wooden furniture, proved to be too light. When combined with a conventional stock, recoil was excessive in fully automatic fire. Their second design was simply a scaled-down AR-10, and immediately proved much more controllable. Winchester entered a design based loosely on their M1 carbine, and Earle Harvey of Springfield attempted to enter a design, but was overruled by his superiors at Springfield, who refused to divert resources from the T44.

In the end, ArmaLite's AR-15 had no competition. The lighter round allowed the rifle to be scaled down, and was smaller and lighter than the previous AR-10. The AR-15 weighed only around 5.5 lb (2.5 kg) empty, 6 lb (2.7 kg) loaded (with a 20 round magazine).

During testing in March 1958, rainwater caused the barrels of both the ArmaLite and Winchester rifles to burst, causing the Army to once again press for a larger round, this time at .258 in (6.6 mm). Nevertheless, they suggested continued testing for cold-weather suitability in Alaska. Stoner was later asked to fly in to replace several parts, and when he arrived he found the rifles had been improperly reassembled. When he returned he was surprised to learn that they too had rejected the design even before he had arrived; their report also endorsed the .258 in (6.6 mm) round. After reading these reports, General Maxwell Taylor became dead-set against the design, and pressed for continued production of the M14.

Not all the reports were negative. In a series of mock-combat situations testing the AR-15, M14 and AK-47, the Army found that the AR-15's small size and light weight allowed it to be brought to bear much more quickly, just as CONARC had suggested. Their final conclusion was that an 8-man team equipped with the AR-15 would have the same firepower as a current 11-man team armed with the M14. They also found that the AR-15, as tested, was more reliable than the M14, suffering fewer stoppages and jams in tests where thousands of rounds were fired.

At this point, Fairchild had spent $1.45 million in development expenses, and wished to divest itself of its small-arms business. Fairchild sold production rights for the AR-15 to Colt Firearms in December 1959, for only $75,000 cash and a 4.5% royalty on subsequent sales. In 1960, ArmaLite was reorganized, and Stoner left the company.

M16 adoption

Curtis LeMay viewed a demonstration of the AR-15 in July 1960. In the summer of 1961, General LeMay had been promoted to the position of USAF Chief of Staff, and requested an order of 80,000 AR-15s for the U.S. Air Force.[21] However under the recommendation of General Maxwell D. Taylor, who advised the Commander in Chief that having two different calibers within the military system at the same time would be problematic, President Kennedy turned down the request.[21] However, Advanced Research Projects Agency, which had been created in 1958 in response to the Soviet Sputnik program, embarked on project AGILE in the spring of 1961. AGILE's priority mission was to devise inventive fixes to the communist problem in South Vietnam.[22] In October 1961, William Godel, a senior man at ARPA, sent 10 AR-15s to South Vietnam to let the allies test them. The reception was enthusiastic, and in 1962 another 1,000 AR-15s were sent to South Vietnam.[23] Special Operations units and advisers working with the South Vietnamese troops filed battlefield reports lavishly praising the AR-15 and the stopping effectiveness of the 5.56 mm cartridge, and pressed for its adoption. However, what no one knew, except the men directly using the AR-15s in Vietnam, were the devastating kills[24] made by the new rifle, photographs of which, showing enemy casualties made by the .223 (5.56 mm) bullet remained classified into the 1980s.[24]

The damage caused by the .223 (5.56mm) "varmint"[24] bullet was easily accounted for. Standard U.S. rifles generally had 12 inch rifling twists inside their barrels (one complete bullet rotation within 12 inches), whereas the AR-15, as designed by Stoner, was to have a 1 in 14 inch rifling twist, as rapid spraying of projectiles at close range would be the norm rather than long range accuracy. However Colt, with its antiquated equipment, had made some of the AR-15s with up to 18 inches per total bullet rotation,[25] thus creating a bullet's flight to wobble while en route to target. The impact of these projectiles on human flesh created horrible wounds; as well as very few prisoners of war.[26]

U.S. Secretary of Defense Robert McNamara now had two conflicting views: the ARPA report favoring the AR-15 and the Pentagon's position on the M14. Even President John F. Kennedy expressed concern, so McNamara ordered Secretary of the Army Cyrus Vance to test the M14, the AR-15 and the AK-47. The Army's test report stated only the M14 was suitable for Army use, but Vance wondered about the impartiality of those conducting the tests. He ordered the Army Inspector General to investigate the testing methods used, who reported that the testers showed favor to the M14.

Secretary Robert McNamara ordered a halt to M14 production in January 1963, after receiving reports that M14 production was insufficient to meet the needs of the armed forces. Secretary McNamara had long been a proponent of weapons program consolidation among the armed services. At the time, the AR-15 was the only rifle that could fulfill a requirement of a "universal" infantry weapon for issue to all services. McNamara ordered the weapon be adopted unmodified, in its current configuration, for immediate issue to all services, despite receiving reports noting several deficiencies with the M16 as a service rifle, including the lack of a chrome-lined bore and chamber, the 5.56 mm projectile's instability under arctic conditions, and the fact that large quantities of 5.56 mm ammunition required for immediate service were not available. In addition, the Army insisted on the inclusion of a forward assist to help push the bolt into battery in the event that a cartridge failed to seat in the chamber through fouling or corrosion. Colt had argued the rifle was a self-cleaning design, requiring little or no maintenance. Colt, Eugene Stoner, and the U.S. Air Force believed that a forward assist needlessly complicated the rifle, adding about $4.50 to its procurement cost with no real benefit. As a result, the design was split into two variants: the Air Force's M16 without the forward assist, and for the other service branches, the XM16E1 with the forward assist.

In November 1963, McNamara approved the Army's order of 85,000 XM16E1s for jungle warfare operations;[27] and to appease General LeMay, the Air Force was granted an order for another 19,000 M16s.[16][28] Meanwhile, the Army carried out another project, the Small Arms Weapons Systems, on general infantry firearm needs in the immediate future. They recommended the immediate adoption of the weapon. Later that year the Air Force officially accepted their first batch as the United States Rifle, Caliber 5.56 mm, M16.

The Army immediately began to issue the XM16E1 (re-named M16A1 on its adoption) to infantry units but the rifle was initially delivered without adequate cleaning supplies or instructions. When the M16 reached Vietnam with U.S. troops in March 1965, reports of jamming and malfunctions in combat began to surface. Although the M14 featured a chrome-lined barrel and chamber to resist corrosion in combat conditions, neither the bore nor the chamber of the M16/XM16E1 was chrome-lined. Several documented accounts of troops killed by enemy fire with jammed rifles broken-down for cleaning eventually brought a Congressional investigation.[29]

| “ | We left with 72 men in our platoon and came back with 19, Believe it or not, you know what killed most of us? Our own rifle. Practically every one of our dead was found with his [M16] torn down next to him where he had been trying to fix it. - Marine Corps Rifleman, Vietnam.[29] |

” |

The root cause of the jamming issues turned out to be a problem with the powder for the ammunition. In 1964 when the Army was informed that DuPont could not mass-produce the nitrocellulose-based powder to the specifications demanded by the M16, the Olin Mathieson Company provided a high-performance ball propellant of nitrocellulose and nitroglycerin. While the Olin WC 846 powder was capable of firing an M16 5.56 mm round at the desired 3,300 ft. per second, it had the unintended consequence of increasing the automatic rate of fire from 850 to 1000 rounds per minute. This would leave behind dirty residue and making the M16 more likely to jam. The problem was resolved by fitting the M16 with a buffer system, slowing the rate of fire back down to 650 to 850 rounds per minute and outfitting all newly produced M16's with a chrome-plated chamber.[30]

On February 28, 1967, the XM16E1 was standardized as the M16A1. Major revisions to the design followed. The rifle was given a chrome-lined chamber (and later, the entire bore) to eliminate corrosion and stuck cartridges, and the rifle's recoil mechanism was re-designed to accommodate Army-issued 5.56 mm ammunition. Rifle cleaning tools and powder solvents/lubricants were issued. Intensive training programs in weapons cleaning were instituted, and a comic book style manual was circulated among the troops to demonstrate proper maintenance.[16] The reliability problems of the M16 diminished quickly, although the rifle's reputation continued to suffer.[16]

According to a February 1968 Department of Defense report the M16 rifle achieved widespread acceptance by U.S. troops in Vietnam. Only 38 of 2100 individuals queried wanted to replace the M16 with another weapon. Of those 38, 35 wanted the CAR-15 (a shorter version of the M16) instead.[31]

NATO standards

In March 1970, the U.S. stated that all NATO forces would eventually adopt the 5.56x45mm cartridge. This shift represented a change in the philosophy of the military's long-held position about caliber size. It was particularly unsettling to the British, whose military had adopted the larger 7.62mm NATO cartridge over their own .280 caliber (7.1 mm) nearly 20 years earlier. From the British point of view, the realization by the U.S. of the effectiveness of a smaller caliber was a belated one.

By the middle of the 1970s, other armies were also looking at an M16-style weapon. A NATO standardization effort soon started, and tests of various rounds were carried out starting in 1977. The U.S. offered their original design, the M193, with no modifications, but there were concerns about its penetration in the face of the wider introduction of body armor. The British offered a modified 5.56 mm round, using a longer and thinner bullet of 4.85 mm. The round had somewhat better ballistics and considerably better penetration, able to reach 600 m and meet their requirements for a squad automatic weapon (light machine gun). The Germans proposed a new 4.7 mm caseless round, which was considerably lighter while offering similar ballistics to the original U.S. design. However, there was distrust in the caseless system due to the possibility of cook off. A final design was offered by the Belgians. Their SS109 round was based on the U.S. cartridge but included a new bullet design, with the same 5.56 mm caliber, but with a small steel tip added to improve penetration.

Testing soon showed that the British and Belgian designs were roughly equal, both outperforming the original U.S. design. In order to get full performance from tracer versions of the SS109, however, barrels would have to use different rifling. Existing 1:12 inch (or 1:300mm) twist barrels reduced the effective range of the SS109 to 90 meters due to lack of stability. While the ideal twist rate for the SS109 projectile is 1:9 inch/1:229mm, a 1:7 inch/1:180mm twist rate was chosen to stabilize the much longer L110 tracer. This tracer was designed to complement the SS109's ballistic performance. The M196 tracer (complement to the M193 ball round) had a burn-out range of 450 meters where the L110 tracer was bright to 800 meters. In the end the Belgian round was chosen. The U.S. Marine Corps was first to adopt the round with the M16A2, introduced in 1982. This was to become the standard U.S. military rifle. The NATO 5.56x45mm standard ammunition produced for U.S. forces is designated M855 for the ball round using an SS109 type projectile and M856 for the tracer using the L110 type projectile.

The M16 series has four main versions: M16A1, M16A2, M16A3, and M16A4. Total worldwide production of M16-style weapons since the design's inception has been approximately 8 million.[2]

Design

The M16's receivers are made of 7075 aluminum alloy, its barrel, bolt, and bolt carrier of steel, and its handguards, pistol grip, and buttstock of plastics. Early models were especially lightweight at 6.5 lb (2.9 kg) without magazine and sling. This was significantly less than older 7.62 mm "battle rifles" of the 1950s and 1960s. It also compares with the 6.5 lb (2.9 kg) AKM without magazine.[32] M16A2 and later variants weigh more (8.5 lb (3.9 kg) loaded) because of the adoption of a thicker barrel profile. The thicker barrel is more resistant to damage when handled roughly and is also slower to overheat during sustained fire. Unlike a traditional "bull" barrel that is thick its entire length, the M16A2's barrel is only thick forward of the handguards. The barrel profile under the handguards remained the same as the M16A1 for compatibility with the M203 grenade launcher. The rifle is the same length as the M16A2.

One distinctive ergonomic feature is a plastic or metal stock directly behind the action, which contains a recoil spring.[33] This serves the dual function of operating spring and recoil buffer.[33] The stock being in line with the bore reduces muzzle rise, especially during automatic fire. Because recoil does not significantly shift the point of aim, faster follow-up shots are possible and user fatigue is reduced.

Another distinctive ergonomic feature is a carrying handle on top of the receiver, with an integrated rear sight assembly and charging handle. This design is a by-product of the original design where the carry handle served to protect the charging handle and mount a scope.[33] In practice, the handle is rarely used to carry the weapon and doing so is expressly prohibited in many military organizations, as it is considered unsafe. Holding the weapon by the pistol grip provides quicker response time and better "muzzle awareness," while a shoulder sling provides a more convenient option when response time is not a concern. More importantly, with the sight plane 2.5 in (63.5 mm) over the bore, the M16 has an inherent parallax problem that can be confounding to shooters. At closer ranges (typically inside 15–20 meters), the shooter must aim high in order to place shots where desired.

Newer models have a "flattop" upper receiver with a Picatinny rail, to which the user can attach either a conventional sighting system or numerous optical devices such as night vision scopes.

The M16 utilizes direct impingement gas operation; energy from high-pressure gas tapped from a non-adjustable port built into the front sight assembly actuates the moving parts in the weapon. Combustion gases travel via a gas tube above the barrel directly into a chamber in the bolt carrier behind the bolt itself, pushing the carrier away from the bolt. This reduces the number of moving parts by eliminating the need for a separate piston and cylinder and it provides better performance in rapid fire by keeping reciprocating masses on the same axis as the bore.

The primary criticism of direct impingement is that fouling and debris from expended gunpowder is blown directly into the breech. As the superheated combustion gas travels down the tube, it expands and cools. This cooling causes vaporized matter to condense as it cools depositing a much greater volume of solids into the operating components of the action. The increased fouling can cause malfunctions if the rifle is not cleaned as frequently as should be. The amount of sooting deposits tends to vary with powder specification, caliber, and gas port design.

In April 2010 TACOM Life Cycle Management Command issued permission for soldiers to camouflage M4/M16 weapons with paint if given command approval.[34]

Production and users

The M16 is the most commonly manufactured 5.56x45mm rifle in the world. Currently, the M16 is in use by 15 NATO countries and more than 80 countries world wide. Together, numerous companies in the United States, Canada, and China have produced more than 8,000,000 rifles of all variants. Approximately 90% are still in operation.[35] The M16 replaced the M14 and M1 carbine as standard infantry rifles of the U.S. armed forces. The M14 continues to see limited service, mostly in sniper, designated marksman, and ceremonial roles.

Users

.jpg)

Afghanistan[36]

Afghanistan[36] Australia[37] (M16A1) (Replaced 1989 by Steyr AUG)

Australia[37] (M16A1) (Replaced 1989 by Steyr AUG) Bangladesh: (Used by Bangladesh military, Special Forces and Counter Terrorism Units)[38]

Bangladesh: (Used by Bangladesh military, Special Forces and Counter Terrorism Units)[38] Barbados[39]

Barbados[39] Belize[39]

Belize[39] Bolivia[39]

Bolivia[39] Brazil[39]

Brazil[39] Brunei[39]

Brunei[39] Cambodia[40]

Cambodia[40] Cameroon[39]

Cameroon[39] Canada: C7 variant is used by the Canadian Armed Forces.[41]

Canada: C7 variant is used by the Canadian Armed Forces.[41] Chile[39]

Chile[39] Democratic Republic of the Congo[40]

Democratic Republic of the Congo[40] Denmark[39]

Denmark[39] Dominican Republic[39]

Dominican Republic[39] East Timor[42]

East Timor[42] Ecuador[39]

Ecuador[39] El Salvador[39]

El Salvador[39] Estonia[43]

Estonia[43] Eritrea

Eritrea Fiji[39]

Fiji[39] Gabon[39]

Gabon[39] Ghana[39]

Ghana[39] Greece[39]

Greece[39] Grenada[39]

Grenada[39] Guatemala[40]

Guatemala[40] Haiti[40]

Haiti[40] India[39]

India[39] Indonesia[39]

Indonesia[39] Iraq: Iraqi army.[44]

Iraq: Iraqi army.[44] Israel[45]

Israel[45] Jamaica[39]

Jamaica[39] Jordan[39]

Jordan[39] South Korea: Manufactured under license by Daewoo.[39]

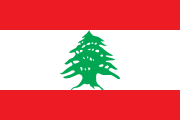

South Korea: Manufactured under license by Daewoo.[39] Lebanon[40]

Lebanon[40] Lesotho[39]

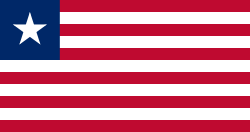

Lesotho[39] Liberia[40]

Liberia[40] Lithuania: Lithuanian Armed Forces.[46]

Lithuania: Lithuanian Armed Forces.[46] Malaysia[39]

Malaysia[39] Mexico[39]

Mexico[39] Morocco[39]

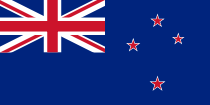

Morocco[39] New Zealand[39] (Replaced 1988 by Steyr AUG)

New Zealand[39] (Replaced 1988 by Steyr AUG) Nepal[47]

Nepal[47] Netherlands: C7 variant is used by the Royal Netherlands Army.[41]

Netherlands: C7 variant is used by the Royal Netherlands Army.[41] Nicaragua[39]

Nicaragua[39] Nigeria[39]

Nigeria[39] Oman[39]

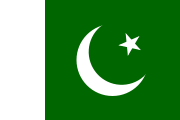

Oman[39] Pakistan: Special Service Group (SSG) of the Pakistan Army.[48]

Pakistan: Special Service Group (SSG) of the Pakistan Army.[48] Panama[39] (M16A1)

Panama[39] (M16A1) Peru[39]

Peru[39] Philippines: Manufactured under license by Elisco Tool and Manufacturing.[39]

Philippines: Manufactured under license by Elisco Tool and Manufacturing.[39] Qatar[39]

Qatar[39] Senegal[49]

Senegal[49] Singapore: Manufactured made under license by ST Kinetics.[40]

Singapore: Manufactured made under license by ST Kinetics.[40] Somalia[39]

Somalia[39] South Africa[39]

South Africa[39] South Korea: Locally produced.[40]

South Korea: Locally produced.[40] Sri Lanka[40]

Sri Lanka[40] Thailand[39] (M16A1/A2/A4)

Thailand[39] (M16A1/A2/A4) Tunisia[39]

Tunisia[39] Turkey[39] (M16A1)

Turkey[39] (M16A1) Uganda[39]

Uganda[39] United Arab Emirates[39]

United Arab Emirates[39] United Kingdom: Special Air Service.[50]

United Kingdom: Special Air Service.[50] United States[51]

United States[51] Uruguay[39]

Uruguay[39] Vietnam[39] (M16A1)

Vietnam[39] (M16A1)

Variants

Pre-Production ArmaLite AR-15

The weapon that eventually became the M16 series only had a vague resemblance to its offspring. The rifle was basically a scaled down AR-10 with an ambidextrous charging handle located within the carrying handle, a narrower front sight "A" frame, and no flash suppressor.[52]

AR-15 (Colt Models 601 & 602)

Colt's first two models produced after the acquisition of the rifle from ArmaLite were the 601 and 602, and these rifles were in many ways clones of the original ArmaLite rifle (in fact, these rifles were often found stamped Colt ArmaLite AR-15, Property of the U.S. Government caliber .223, and no reference to being a M16).[53] The 601 and 602 are easily identified by their flat lower receivers without raised surfaces around the magazine well and occasionally green or brown furniture. The 601 was adopted first of any of the rifles by the USAF, and was quickly supplemented with the XM16 (Colt Model 602) and later the M16 (Colt Model 604) as improvements were made. There was also a limited purchase of 602s, and a number of both of these rifles found their way to a number of Special Operations units then operating in South East Asia, most notably the U.S. Navy SEALs. The only major difference between the 601 and 602 is the switch from the original 1:14-inch rifling twist to the more common 1:12-inch twist. These weapons were equipped with a triangular charging handle and a bolt hold open device that lacked a raised lower engagement surface. The bolt hold open device had a slanted and serrated surface that had to be engaged with a bare thumb, index finger, or thumb nail because of the lack of this surface.

The United States Air Force continued to use the AR-15 marked rifles in various configurations into the 1990s.

M16

Variant originally adopted by the U.S. Air Force. This was the first M16 adopted operationally. This variant had triangular handguards, butt stocks with out a compartment for the storage of a cleaning kit,[54] a three-pronged flash suppressor, and no forward assist. Bolt carriers were originally chrome plated and slick-sided, lacking forward assist notches. Later, the chrome plated carriers were dropped in favor of Army issued notched and parkerized carriers though the interior portion of the bolt carrier is still chrome-lined. The Air Force continues to operate these weapons and upgrades them as parts wear or break and through attrition.

The M16 was also adopted by the British SAS, who used it to effect during the Falklands War.[55]

XM16E1 and M16A1 (Colt Model 603)

The U.S. Army XM16E1 was essentially the same weapon as the M16 with the addition of a forward assist and corresponding notches in the bolt carrier. The M16A1 was the finalized production model in 1967. To address issues raised by the XM16E1's testing cycle, a closed, bird-cage flash suppressor replaced the XM16E1's three-pronged flash suppressor which caught on twigs and leaves. Various other changes were made after numerous problems in the field. Cleaning kits were developed and issued while barrels with chrome-plated chambers and later fully-lined bores were introduced.

With these and other changes, the malfunction rate slowly declined and new soldiers were generally unfamiliar with early problems. A rib was built into the side of the receiver on the XM16E1 to help prevent accidentally pressing the magazine release button while closing the ejection port cover. This rib was later extended on production M16A1s to help in preventing the magazine release from inadvertently being pressed. The hole in the bolt that accepts the cam pin was crimped inward on one side, in such a way that the cam pin may not be inserted with the bolt installed backwards, which would cause failures to eject until corrected. The M16A1 remains in service in limited numbers in the United States but is still standard issue in many world armies.

M16A2

The development of the M16A2 rifle was originally requested by the United States Marine Corps as a result of the USMC's combat experience in Vietnam with the XM16E1 and M16A1.[9] The Marines were the first branch of the U.S. Armed Forces to adopt the M16A2 in the early/mid 1980s with the United States Army following suit in the late 1980s. Modifications to the M16A2 were extensive. In addition to the new rifling, the barrel was made with a greater thickness in front of the front sight post to resist bending in the field and to allow a longer period of sustained fire without overheating. The rest of the barrel was maintained at the original thickness to enable the M203 grenade launcher to be attached.[9] The front sight was now a square post with 4 detent positions, adjustable for vertical zeroing by using a cartridge, nail or special tool. A new adjustable rear sight was added, allowing the rear sight to be dialed in for specific range settings between 300 and 800 meters to take full advantage of the ballistic characteristics of the new SS109 rounds and to allow windage adjustments without the need of a tool or cartridge.[9] The flash suppressor was again modified, this time to be closed on the bottom so it would not kick up dirt or snow when being fired from the prone position, and acting as a recoil compensator.[56] The front grip was modified from the original triangular shape to a round one, which better fitted smaller hands and could be fitted to older models of the M16.[9] The new handguards were also symmetrical so that armories need not separate left and right spares. The handguard retention ring was tapered to make it easier to install and uninstall the handguards.[9] A notch for the middle finger was added to the pistol grip, as well as more texture to enhance the grip. The buttstock was lengthened by 5/8 inch (16 mm).[9] The new buttstock became ten times stronger than the original due to advances in polymer technology since the early 1960s. Original M16 stocks were made from fiberglass-impregnated resin; the newer stocks were engineered from DuPont Zytel glass-filled thermoset polymers. The new stock included a fully textured polymer buttplate for better grip on the shoulder, and retained a panel for accessing a small compartment inside the stock, often used for storing a basic cleaning kit. The heavier bullet reduces muzzle velocity from 3,200 feet per second (980 m/s), to about 3,050 feet per second (930 m/s). The A2 also uses a faster twist rifling to allow the use of a trajectory-matched tracer round. A spent case deflector was incorporated into the upper receiver immediately behind the ejection port to prevent cases from striking left-handed users.[9]

The action was also modified, replacing the fully-automatic setting with a three-round burst setting.[9] When using a fully-automatic weapon, poorly trained troops often hold down the trigger and "spray" when under fire. The U.S. Army concluded that three-shot groups provide an optimum combination of ammunition conservation, accuracy and firepower. There are mechanical flaws in the M16A2 burst mechanism. The trigger group does not reset when the trigger is released. If the user releases the trigger between the second and third round of the burst, for example, the next trigger pull would only result in a single shot. Even in semi-automatic mode, the trigger group mechanism affects weapon handling. With each round fired, the trigger group cycles through one of the three stages of the burst mechanism. Worse, the trigger pull at each of these stages may vary as much as 6 lbf (27 N) in pressure differential, detracting from accuracy.

All together, the M16A2's new features added weight and complexity to the M16 series. Critics also point out that neither of the rear sight apertures is ideally sized. The smaller aperture was described as being too small, making quick acquisition of the front sight post difficult; and the larger aperture was described as being too large, resulting in decreased accuracy. To make matters worse, the rear sight apertures are not machined to be on the same plane. In other words, the point of impact changes when the user changes from one aperture to the other. The rear sight's range adjustment feature is rarely used in combat as soldiers tend to leave the rear sight on its lowest range setting of 300 meters. This distance is seen by many as an excessively long range for the minimum setting, given that most engagements take place at significantly shorter ranges. Despite criticism, a new rifle was needed both to comply with NATO standardization of the SS109 (M855) and to replace aging Vietnam era weapons in the inventory.

M16A3

The M16A3 was a fully-automatic variant of the M16A2 adopted in small numbers around the time of the introduction of the M16A2, primarily by the U.S. Navy for use by SEAL, Seabee, and Security units.[57] It features the M16A1 trigger group providing "safe", "semi-automatic", and "fully-automatic" modes.

The M16A3 is often incorrectly described as the fully-automatic version of the M16A4 or an M16A2 with a Picatinny rail. This misunderstanding likely stems from the use of the "A3" designation by Colt and other manufacturers to describe commercial AR-15 type rifles before the official adoption of the M16A3 or M16A4. Colt used the "A3" designation in the hopes of winning military contracts as they also did with the terms, "M4" and "M5".

M16A4

The M16A4, now standard issue for front-line U.S. Marine Corps and some U.S. Army units, replaces the combination fixed carry handle/rear iron sight with a MIL-STD-1913 Picatinny rail, allowing for the rifle to be equipped with a carry handle and/or most military and consumer scopes or sighting systems.[57] Military issue rifles are also equipped with a Knight's Armament Company M5 RAS handguard, allowing vertical grips, lasers, tactical lights, and other accessories to be attached, coining the designation M16A4 MWS (or Modular Weapon System) in U.S. Army field manuals.[58]

Derivatives

Colt Model 655 and 656 "Sniper" variants

With the expanding conflict in South East Asia, Colt developed two rifles of the M16 pattern for evaluation as possible light sniper or designated marksman rifles. The Colt Model 655 M16A1 Special High Profile was essentially a standard A1 rifle with a heavier barrel and a scope mount that attached to the rifle's carry handle. The Colt Model 656 M16A1 Special Low Profile had a special upper receiver with no carrying handle. Instead, it had a low-profile iron sight adjustable for windage and a Weaver base for mounting a scope, a precursor to the Colt and Picatinny rails. It also had a hooded front iron sight in addition to the heavy barrel. Both rifles came standard with either a Leatherwood/Realist scope 3-9x Adjustable Ranging Telescope. Some of them were fitted with a Sionics noise and flash suppressor. Neither of these rifles were ever standardized.

These weapons can be seen in many ways to be predecessors of the U.S. Army's SDM-R and the USMC's SAM-R weapons.

XM177

In Vietnam, some soldiers were issued a carbine version of the M16 called the XM177. The XM177 had a shorter 10 in (254 mm) barrel and a telescoping stock, which made it substantially more compact. It also possessed a combination flash hider/sound moderator to reduce problems with muzzle flash and loud report. The USAF's GAU-5/A (XM177) and the U.S. Army's XM177E1 variants differed over the latter’s inclusion of a forward assist, although some GAU-5s do have the forward assist. The final USAF GAU-5A/A and U.S. Army XM177E2 had an 11.5 in (292 mm) barrel with a longer flash/sound suppressor. The lengthening of the barrel was to support the attachment of Colt's own XM148 40 mm grenade launcher. These versions were also known as the Colt Commando model commonly referenced and marketed as the CAR-15. The variants were issued in limited numbers to special forces, helicopter crews, Air Force pilots, Air Force Security Police Military Working Dog (MWD) handlers, officers, radio operators, artillerymen, and troops other than front line riflemen. Some USAF GAU-5A/As were later equipped with even longer 14.5 inch 1/12 rifled barrels as the two shorter versions were worn out. The 14.5-inch (370 mm) barrel allowed the use of MILES gear and for bayonets to be used with the Sub-Machine Guns (as The USAF described them). By 1989 the USAF started to replace the earlier barrels with 1/7 rifled models.

Also used by the SAS, who used it to effect during the Falklands War.[55]

Colt Model 733

Colt also returned to the original "Commando" idea, with its Model 733, essentially a modernized XM177E2 with many of the features introduced on the M16A2.

M231 Firing Port Weapon (FPW)

M231 Firing Port Weapon (FPW) is an adapted version of the M16 assault rifle for firing from ports on the M2/M3 Bradley AFV. The infantry's normal M16s are too long for use in a "buttoned up" APC, so the FPW was developed to provide a suitable weapon for this role. Designed by the Rock Island Arsenal, the M231 FPW remains in service, although all but the rear two firing ports on the Bradley have been removed. The M231 FPW fires from the open bolt and is only configured for fully automatic fire.

Mk 4 Mod 0

The Mk 4 Mod 0 was a variant of the M16A1 produced for the U.S. Navy SEALs during the conflict in Vietnam and adopted in April 1970. It differed from the basic M16A1 primarily in being optimized for maritime operations and coming equipped with a sound suppressor. Most of the operating parts of the rifle were coated in Kal-Guard, a quarter-inch hole was drilled through the stock and buffer tube for drainage, and an O-ring was added to the end of the buffer assembly. The weapon could reportedly be carried to the depth of 200 feet (60 m) without damage. The initial Mk 2 Mod 0 Blast Suppressor was based on the U.S. Army's Human Engineering Lab's (HEL) M4 noise suppressor. The HEL M4 vented gas directly from the action, requiring a modified bolt carrier. A gas deflector was added to the charging handle to prevent gas from contacting the user. Thus, the HEL M4 suppressor was permanently mounted though it allowed normal semi-automatic and automatic operation. If the HEL M4 suppressor were removed, the weapon would have to be manually loaded after each single shot. On the other hand, the Mk 2 Mod 0 blast suppressor was considered an integral part of the Mk 4 Mod 0 rifle, but it would function normally if the suppressor were removed. The Mk 2 Mod 0 blast suppressor also drained water much more quickly and did not require any modification to the bolt carrier or to the charging handle. In the late 1970s, the Mk 2 Mod 0 blast suppressor was replaced by the Mk 2 blast suppressor made by Knight's Armament Company (KAC). The KAC suppressor can be fully submerged and water will drain out in less than eight seconds. It will operate without degradation even if the M16A1 is fired at the maximum rate of fire. The U.S. Army replaced the HEL M4 with the much simpler Studies in Operational Negation of Insurgency and Counter-Subversion (SIONICS) MAW-A1 noise and flash suppressor.

Mark 12

Developed to increase the effective range of soldiers in the designated marksman role, the US Navy developed the Mark 12 Special Purpose Rifle (SPR). Configurations in service vary, but the core of the Mark 12 SPR is an 18" heavy barrel with muzzle brake and free float tube. This tube relieves pressure on the barrel caused by standard handguards and greatly increases the potential accuracy of the system. Also common are higher magnification optics ranging from the 6× power Trijicon ACOG to the Leupold Mark 4 Tactical rifle scopes. Firing Mark 262 Mod 0 ammunition with a 77gr Open tip Match bullet, the system has an official effective range of 600+ meters. However published reports of confirmed kills beyond 800 m from Iraq and Afghanistan are not uncommon.

M4 carbine

The M4 carbine was developed from various outgrowths of these designs, including a number of 14.5-inch (368 mm)-barreled A1 style carbines. The XM4 (Colt Model 720) started its trials in the mid-80s, with a 14.5-inch (368 mm) barrel. Officially adopted as a replacement for the M3 "Grease Gun" (and the Beretta M9 and M16A2 for select troops) in 1994, it was used with great success in the Balkans and in more recent conflicts, including the Afghanistan and Iraq theaters. The M4 carbine has a three-round burst firing mode, while the M4A1 carbine has a fully automatic firing mode. Both have a Picatinny rail on the upper receiver, allowing the carry handle/rear sight assembly to be replaced with other sighting devices.

International derivatives

C7 and C8

The Diemaco C7 and C8 are updated variants of the M16 developed and used by the Canadian Forces and are now manufactured by Colt Canada. The C7 is a further development of the experimental M16A1E1. Like earlier M16s, it can be fired in either single shot or automatic mode, instead of the burst function selected for the M16A2. The C7 also features the structural strengthening, improved handguards, and longer stock developed for the M16A2. Diemaco changed the trapdoor in the buttstock to make it easier to access and a half-inch spacer is available to adjust stock length to user preference. The most easily noticeable external difference between American M16A2s and Diemaco C7s is the retention of the A1 style rear sights. Not easily apparent is Diemaco's use of hammer-forged barrels. The Canadians originally desired to use a heavy barrel profile instead.

The C7 has been developed to the C7A1, with a Weaver rail on the upper receiver for a C79 optical sight, and to the C7A2, with different furniture and internal improvements. The Diemaco produced Weaver rail on the original C7A1 variants does not meet the M1913 'Picatinny' standard, leading to some problems with mounting commercial sights. This is easily remedied with minor modification to their the upper receiver or the sight itself. Since Diemaco's acquisition by Colt to form Colt Canada, all Canadian produced flattop upper receivers are machined to the M1913 standard.

The C8 is the carbine version of the C7.[59] The C7 and C8 are also used by Hærens Jegerkommando, Marinejegerkommandoen and FSK (Norway), Military of Denmark (all branches), the Royal Netherlands Army and Netherlands Marine Corps as its main infantry weapon. Following trials, variants became the weapon of choice of the British SAS.

Others

- The Chinese Norinco CQ-311 is an unlicensed derivative of the M16A1 made specifically for export, with the most obvious external differences being in its handguard and revolver-style pistol grip.

- Khaybar KH2002, is an Iranian bullpup conversion of the locally produced S-5.56 rifle. Iran intends to replace the standard issue weapon of its armed forces with the Khaybar. The S-5.56 assault rifle itself is an Iranian M16 derivative based on the Norinco CQ. Two versions of the S-5.56 include the S-5.56A1, used for M-193-type bullets while the S-5.56A3 is used for SS-109-type bullets.

- The MSSR rifle developed as an effective, low cost sniper rifle by the Philippine Marine Corps Scout Snipers. The Special Operations Assault Rifle (SOAR) assault carbine was developed by Ferfrans based on the M16 rifle. It is used by the Special Action Force.

- Taiwan uses piston driven M16-based weapons as their standard rifle. These include the T65, T86 and T91 assault rifles.

Summary

| Colt model no. | Military designation | Barrel Length | Barrel | Handguard type | Buttstock type | Pistol grip type | Lower receiver type | Upper receiver type | Rear sight type | Front sight type | Muzzle device | Forward assist? | Case deflector? | Bayonet lug? | Trigger pack |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 601 | AR-15 | 20 in (508 mm) | A1 profile (1:14 twist) | Green or brown full-length triangular | Green or brown fixed A1 | A1 | A1 | A1 | A1 | A1 | Duckbill flash suppressor | No | No | Yes | Safe-Semi-Auto |

| 602 | AR-15 or XM16 | 20 in (508 mm) | A1 profile (1:12 twist) | Full-length triangular | Fixed A1 | A1 | A1 | A1 | A1 | A1 | Duckbill or three-prong flash suppressor | No | No | Yes | Safe-Semi-Auto |

| 603 | XM16E1 | 20 in (508 mm) | A1 profile (1:12 twist) | Full-length triangular | Fixed A1 | A1 | A1 | A1 | A1 | A1 | Three-prong or M16A1 birdcage flash suppressor | Yes | No | Yes | Safe-Semi-Auto |

| 603 | M16A1 | 20 in (508 mm) | A1 profile (1:12 twist) | Full-length triangular | Fixed A1 | A1 | A1 | A1 | A1 | A1 | M16A1-style birdcage flash suppressor | Yes | No | Yes | Safe-Semi-Auto |

| 604 | M16 | 20 in (508 mm) | A1 profile (1:12 twist) | Full-length triangular | Fixed A1 | A1 | A1 | A1 | A1 | A1 | Three-prong or M16A1-style birdcage flash suppressor | No | No | Yes | Safe-Semi-Auto |

| 645 | M16A1E1/PIP | 20 in (508 mm) | A2 profile (1:7 twist) | Full-length ribbed | Fixed A2 | A1 | A1 or A2 | A1 or A2 | A1 or A2 | A2 | M16A1 or M16A2-style birdcage flash suppressor | Yes | Yes or No | Yes | Safe-Semi-Auto or Safe-Semi-Burst |

| 645 | M16A2 | 20 in (508 mm) | A2 profile (1:7 twist) | Full-length ribbed | Fixed A2 | A2 | A2 | A2 | A2 | A2 | M16A2-style birdcage flash suppressor | Yes | Yes | Yes | Safe-Semi-Burst |

| 645E | M16A2E1 | 20 in (508 mm) | A2 profile (1:7 twist) | Full-length ribbed | Fixed A2 | A2 | A2 | Flattop with Colt Rail | Flip-up | Folding | M16A2-style birdcage flash suppressor | Yes | Yes | Yes | Safe-Semi-Burst |

| N/A | M16A2E2 | 20 in (508 mm) | A2 profile (1:7 twist) | Full-length semi-beavertail w/ HEL guide | Retractable ACR | ACR | A2 | Flattop with Colt rail | None | A2 | ACR muzzle brake | Yes | Yes | Yes | Safe-Semi-Burst |

| 646 | M16A2E3/M16A3 | 20 in (508 mm) | A2 profile (1:7 twist) | Full-length ribbed | Fixed A2 | A2 | A2 | A2 | A2 | A2 | M16A2-style birdcage flash suppressor | Yes | Yes | Yes | Safe-Semi-Auto |

| 655 | M16A1 Special High Profile | 20 in (508 mm) | HBAR profile (1:12 twist) | Full-length triangular | Fixed A1 | A1 | A1 | A1 | A1 | A1 | M16A1-style birdcage flash suppressor | Yes | No | Yes | Safe-Semi-Auto |

| 656 | M16A1 Special Low Profile | 20 in (508 mm) | HBAR profile (1:12 twist) | Full-length triangular | Fixed A1 | A1 | A1 | A1 with modified Weaver base | Low Profile A1 | Hooded A1 | M16A1-style birdcage flash suppressor | Yes | No | Yes | Safe-Semi-Auto |

| 945 | M16A2E4/M16A4 | 20 in (508 mm) | A2 profile (1:7 twist) | Full-length ribbed or KAC M5 RAS | Fixed A2 | A2 | A2 | Flattop with MIL-STD-1913 rail | None | A4 | M16A2-style birdcage flash suppressor | Yes | Yes | Yes | Safe-Semi-Burst |

| Colt model no. | Military designation | Barrel Length | Barrel | Handguard type | Buttstock type | Pistol grip type | Lower receiver type | Upper receiver type | Rear sight type | Front sight type | Muzzle device | Forward assist? | Case deflector? | Bayonet lug? | Trigger pack |

Future replacement

Background

Throughout the 1970s, the Army experimented with various materials to replace brass in cartridge casings. Brass has a number of qualities that make it almost ideal for a cartridge, including low friction against steel, making it easier to extract, and the ease with which casings can be manufactured. However, brass is also dense and expensive, so replacing it could lower both the cost and weight of the ammunition.

Aluminum and steel were popular materials for complete rounds, and AAI successfully developed a plastic blank. Completely caseless ammunition was also studied on several occasions, notably the German 4.7 mm designs, and this concept is now being continued with the Lightweight Small Arms Technologies Program.

Later in the 1980s, the Advanced Combat Rifle program was run to find a replacement for the M16. Colt entered a modified M16A2 known as the Colt ACR, which used duplex rounds, a system that lowered recoil by 40% to improve repeating shots, and added a 3.5x scope. This weapon, designated M16A2E2, also featured a "guide" of sorts as part of a special handguard developed by the U.S. Army Human Engineering Laboratory designed to assist in snap-shooting, and a carbine style stock very similar to the recent stock developed by the Naval Surface Warfare Center Crane Division.

The Steyr ACR used new flechette ammunition that was nominally called 5.56 mm, with a very high 4,750 ft/s (1,448 m/s) muzzle velocity. Other variants experimented with caseless ammunition technologies as well.

Replacement designs

In the 1980s, the M249 was issued to infantry units, replacing some M60s and some M16A1s at the squad level. In the 1990s the M4 carbine took over the operational role of the M3 submachine gun, some M9s, and many M16A2s. The U.S. Air Force mostly uses M4 and GAU-5 carbines for security squadrons and M16A2s for non-security personnel. The U.S. Navy decided to retain the M16A2 and M16A3 for its units that use rifles like the U.S. Navy Seabees. The U.S. Army and Marine Corps have largely relegated the M16A2 to non-combat roles, choosing instead the M16A4 and M4. Further, the M16 never entirely replaced the M14 in all roles, which continues to be used in a number of niche applications throughout the Armed Forces, especially with the U.S. Navy.

Replacement of the M16 family has been proposed at various points, and its longevity is in part due to a series of failures in projects meant to replace it, driven largely by the requirement for a significant improvement. Immediately after the introduction of the M16, the Marine Corps sought to adopt the Stoner 63. Although they found it superior in most ways, it was still at an early stage of development; the Marines chose the technically inferior but mature M16. The Advanced Combat Rifle program in the 1980s produced weapons that were superior in some ways, but none improved upon the M16 series enough to replace it. It was also potentially going to be replaced by the SABR, from the OICW project. The weapon system originally planned by the OICW project was put on hold around the turn of century, in favor of a simpler new 5.56 mm rifle project that offered less far-reaching improvements. The resulting XM8 rifle was also intended as a potential replacement for the M16 family. However, this program too ran into problems around 2004-05, and was put on hold in favor of an open competition for what became known as the OICW Increment 1. (Increment 2 is the standalone XM25 Individual Airburst Weapon System, and Increment 3 is the XM29 OICW, a weapon that combined the earlier two increments.) This competition was subsequently put on hold in the summer of 2005 to take into account input from other services, and on October 31, 2005, the competition was canceled.

A partial replacement for the M16 rifle is the SOF Combat Assault Rifle (SCAR), designated Mk 16. The 5.56x45 Mk 16 emerged as the winner of a USSOCOM competition to find a new rifle for Special Operations Forces in 2003. Most of the SCAR's basic controls (pistol grip, magazine release, selector lever, and bolt release) share the same location and function as on the M16 and M4 they are supplementing.

Since the cancellation of the XM8 program, and into 2008, the LSAT program has been pursued for the next generation of U.S. small arms. The program has already produced practical results and is currently projected to provide the next U.S. military rifle.[60] Development of a rifle using LSAT began in 2008 and could enter production by 2010.[60]

Several companies have been working on and creating potential candidates for the U.S. military's next primary weapon. The Heckler & Koch HK416 has been in use by Delta Force since 2004. The HK416 is offered as a conversion kit that can retrofit current M4 carbines. The H&K 416 recently won a testing competition for the US Marine Corps Infantry Automatic Rifle program and entered final testing as the M27 in summer 2010.[61] The H&K 416 is also one of several M4 designs on the front competitors of a new Army M4 upgrade competition. The H&K's design replaces the direct impingement gas system with a newer piston design which is easier to maintain in the field. The reason to build a new M4 is to produce a new more reliable carbine for US troops in a few years.

During the late 1990s and early 2000s the IMI developed the IMI Tavor TAR-21 which has supplemented the M16s and M4s in service with the Israeli Defense Force.

See also

- Comparison of the AK-47 and M16

- List of individual weapons of the U.S. armed forces

- Bushmaster ACR

- Daewoo K2, South Korean assault rifle

- Robinson Arms XCR

- T65 assault rifle, AR-15 variant developed by ROC Army

Notes

- ↑ Ezell, Virginia Hart (November 2001). "Focus on Basics, Urges Small Arms Designer". National Defense (National Defense Industrial Association). http://www.nationaldefensemagazine.org/archive/2001/November/Pages/Focus_on4174.aspx.

- ↑ 2.0 2.1 Colt Weapon Systems.

- ↑ "Colt Weapon Systems". Colt.com. http://www.colt.com/mil/M16_2.asp. Retrieved 2010-08-22.

- ↑ American Rifle: A Biography, Alexander Rose (2009) p. 375-376

- ↑ The SAS Training Manual, Chris McNab, (2002) pp. 108-109

- ↑ "Scientific Evidence for 'Hydrostatic Shock'", Michael Courtney and Amy Courtney, (2008)

- ↑ Rose, pp. 380 & 392.

- ↑ Urdang, p. 801.

- ↑ 9.00 9.01 9.02 9.03 9.04 9.05 9.06 9.07 9.08 9.09 9.10 9.11 Venola, Richard (2005). "What a Long Strange Trip It's Been". Book of the AR-15 1 (2): 6–18.

- ↑ Ford, Daniel (2001). The Only War We've Got: Early Days in South Vietnam. ISBN 9780595175512. http://books.google.com/?id=sV_K3L6hTqEC.

- ↑ H&R "About Us" page.

- ↑ The Gun Zone.

- ↑ Sabre Defence Industries Awarded M16 Rifle Contract.

- ↑ AR15 Manufacturers & Builders.

- ↑ Regulations Prescribing Certain Firearms and other Weapons, Components and Parts of Weapons, Accessories, Cartridge Magazines, Ammunition and Projectiles as Prohibited or Restricted, SOR/98-462. Canlii. 29-06-2010

- ↑ 16.0 16.1 16.2 16.3 16.4 16.5 16.6 16.7 Ezell, Edward Clinton (1983). Small Arms of the World. New York: Stackpole Books. pp. 46–47. ISBN 978-0880296014.

- ↑ Marshall, S. L. A. (1966). Men against Fire:The Problem of Combat Command in Future War. New York City: William Morrow and Company. pp. 50–60.

- ↑ Hall, Donald L. (1952). An Effectiveness Study of the Infantry Rifle. Maryland: Army Ballistic Research Lab, Aberdeen Proving Ground. http://handle.dtic.mil/100.2/AD377335.

- ↑ Afonso, Aniceto and Gomes, Carlos de Matos, Guerra Colonial (2000), ISBN 972-46-1192-2, pp. 183-184.

- ↑ Hutton, Robert (ed.), The .223, Guns & Ammo Annual Edition, 1971.

- ↑ 21.0 21.1 Rose, p. 372.

- ↑ Rose, pp. 372-373.

- ↑ Rose, pp. 373-373.

- ↑ 24.0 24.1 24.2 Rose, p. 373.

- ↑ Rose, p. 375.

- ↑ Rose, p. 374.

- ↑ Rose, pp. 380, 392.

- ↑ Rose, p. 380.

- ↑ 29.0 29.1 "Defense: Under Fire". Time Magazine, 9 June 1967.

- ↑ Defense: Powder Pains Time Magazine, 8 September 1967.

- ↑ [1], p. 34.

- ↑ weight without magazine of AK (1949) - 3.9 kg, AK (1955) - 3.5 kg, AKM (1959) - 2.9 kg Field manual for AK (Наставление по стрелковому делу 7.62-мм автомат Калашникова (АК)); Field manual for AKM and AKMS (Наставление по стрелковому делу 7.62-мм модернизированный автомат Калашникова (АКМ и АКМС))

- ↑ 33.0 33.1 33.2 Ezell, Edward Clinton (1983). Small Arms of the World. New York: Stackpole Books. pp. 746–762. ISBN 978-0880296014.

- ↑ Dawson, D. "Crib Notes for Soldiers - Weapons Painting 101". http://peosoldier.armylive.dodlive.mil/2010/05/14/crib-notes-for-soldiers-%E2%80%93-weapons-painting-101/. Retrieved 16 May 2010.

- ↑ Customers / Weapon users, Colt Weapon Systems.

- ↑ Fishel, Justin (2007-12-04). "U.S. Military to Provide Afghan Army With M-16 Rifles". FOXNews.com. http://www.foxnews.com/story/0,2933,315121,00.html.

- ↑ "Australian weapons, Viet Nam and since". Diggerhistory.info. 2002-11-11. http://www.diggerhistory.info/pages-weapons/allied_recent.htm. Retrieved 2010-08-22.

- ↑ "Small Arms | Bangladesh Military Forces | BDMilitary.com - The voice of the Bangladesh Armed Forces". BDMilitary.com. http://www.bdmilitary.com/index.php?option=com_content&view=article&id=71&Itemid=95. Retrieved 2010-08-22.

- ↑ 39.00 39.01 39.02 39.03 39.04 39.05 39.06 39.07 39.08 39.09 39.10 39.11 39.12 39.13 39.14 39.15 39.16 39.17 39.18 39.19 39.20 39.21 39.22 39.23 39.24 39.25 39.26 39.27 39.28 39.29 39.30 39.31 39.32 39.33 39.34 39.35 39.36 39.37 39.38 39.39 39.40 39.41 Jane's Special Forces Recognition Guide, Ewen Southby-Tailyour (2005) p. 446

- ↑ 40.0 40.1 40.2 40.3 40.4 40.5 40.6 40.7 40.8 "Report: Profiling the Small Arms Industry - World Policy Institute - Research Project". World Policy Institute. November 2000. http://www.worldpolicy.org/projects/arms/reports/smallarms.htm. Retrieved 2010-07-15.

- ↑ 41.0 41.1 Miller, David (2001). The Illustrated Directory of 20th Century Guns. Salamander Books Ltd. ISBN 1-84065-245-4.

- ↑ Jane's Sentinel Security Assessment - Southeast Asia. Issue 20 – 2007. Pages 146 and 152.

- ↑ "Eesti Kaitsevägi - Tehnika - Automaat M-16 A1". Mil.ee. http://www.mil.ee/?menu=tehnika1&sisu=m16a1. Retrieved 2008-09-08.

- ↑ "First steps to arming Iraq's soldiers". BBC News. 2007-05-18. http://news.bbc.co.uk/2/hi/middle_east/6665759.stm. Retrieved 2010-05-12.

- ↑ John Pike (2003-12-17). "Israel's army phases out country's iconic Uzi submachine gun". Globalsecurity.org. http://www.globalsecurity.org/org/news/2003/031217-uzi.htm. Retrieved 2010-08-22.

- ↑ "Lietuvos kariuomenė :: Ginkluotė ir karinė technika » Automatiniai šautuvai » Automatinis šautuvas M-16" (in (Lithuanian)). Kariuomene.kam.lt. 2009-04-17. http://kariuomene.kam.lt/lt/ginkluote_ir_karine_technika/automatiniai_sautuvai/automatinis_sautuvas_m-16.html. Retrieved 2010-08-22.

- ↑ "Nepal takes delivery of US rifles". BBC News. 2003-01-06. http://news.bbc.co.uk/2/hi/south_asia/2631939.stm. Retrieved 2010-05-12.

- ↑ "Pakdef.info — Pakistan Military Consortium: Special Service Group". Saad, S.; Ali, M.; Shabbir, Usman. 1998. http://www.pakdef.info/pakmilitary/army/regiments/ssg.html. Retrieved 2009-08-15.

- ↑ "Army seeks Senegal ear-choppers". BBC News. 2008-05-09. http://news.bbc.co.uk/2/hi/africa/7392685.stm. Retrieved 2010-05-12.

- ↑ Poyer, Joe. "Modern Firearms - AR-15 M16 M16A1 M16A2 M16A3 assault rifle". World.guns.ru. http://world.guns.ru/assault/as18-e.htm. Retrieved 2010-08-22.

- ↑ "M-16 Rifle Fact File for the United States Army". Army.mil. http://www.army.mil/factfiles/equipment/individual/m16.html. Retrieved 2010-08-22.

- ↑ Page 744 "Small Arms of the World" 12th revised Edition by Edward Clinton Ezell.

- ↑ Pages 744-759 "Small Arms of the World" 12th Revised Edition by Edward Clinton Ezell.

- ↑ Page 754 "Small Arms of the World" 12th Revised Edition by Edward Clinton Ezell.

- ↑ 55.0 55.1 Special Operations.com.

- ↑ Hogg, Ian; Weeks, John (2000). Military Small Arms of the 20th Century (7 ed.). Krause Publications. p. 292. ISBN 9780873418249. http://books.google.com/?id=teAAHt1GaE8C&q=Military+Small+Arms+of+the+20th+Century&dq=Military+Small+Arms+of+the+20th+Century.

- ↑ 57.0 57.1 "US Navy, Marines Buy M-16 Rifles". Defense Industry Daily. 2 January 2008. http://www.defenseindustrydaily.com/the-usas-m-16-rifle-purchases-04517/.

- ↑ US Army Field Manual: RIFLE MARKSMANSHIP M16A1, M16A2/3, M16A4 and M4 CARBINE. 24 April 2003. http://www.globalsecurity.org/military/library/policy/army/fm/3-22-9/c02.htm#2_1.

- ↑ Canadian Forces Automatic Rifles. Canadian American Strategic Review. Retrieved: 2009-08-23.

- ↑ 60.0 60.1 Bruce, Robert. "LSAT The Future of Small Arms Now?". American Rifleman. National Rifle Association. http://www.nrapublications.org/TAR/LSAT.asp. Retrieved 2008-09-08.

- ↑ Lamothe, Dan (July 2, 2010). "Conway eyes additional testing for auto-rifle". Marine Corps Times. http://www.marinecorpstimes.com/news/2010/07/marine_IAR_070110w/. Retrieved 2 July 2010.

References

- Modern Warfare, Published by Mark Dartford, Marshall Cavendish (London) 1985

- Afonso, Aniceto and Gomes, Carlos de Matos, Guerra Colonial (2000), ISBN 9724611922

- Ezell, Edward Clinton (1984). The Great Rifle Controversy: Search for the Ultimate Infantry Weapon from World War II Through Vietnam and Beyond. Harrisburg, Pennsylvania: Halsted Press. ISBN 9780811707091.

- Hughes, David R. (1990). The History and Development of the M16 Rifle and its Cartridge. Oceanside, California: Armory Publications.

- Hutton, Robert, The .223, Guns & Ammo Annual Edition, 1971.

- McNaugher, Thomas L. "Marksmanship, Mcnamara and the M16 Rifle: Organisations, Analysis and Weapons Acquisition", http://www.rand.org/pubs/papers/P6306/

- Pikula, Sam (Major), The ArmaLite AR-10, 1998

- Rose, Alexander. American Rifle-A Biography. 2008; Bantam Dell Publishing. ISBN 978-0-553-80517-8.

- Stevens, R. Blake and Edward C. Ezell. (1994). The Black Rifle: M16 Retrospective, Ontario: Collector Grade Publications.

- Urdang, Laurence, Editor in Chief. The Random House Dictionary of the English Language. 1969; Random House/New York.

External links

- Colt Manufacturing: The M16A4 Rifle

- PEO Soldier M16 fact sheet

- AR15.com, the largest M-16/AR-15 Resource on the Web

- The Gun Zone: A 5.56 mm Timeline

- The AR-15/M16 Magazine FAQ

- Combat Training with the M16 Manual (PDF)

- Rifle Marksmanship M16A1, M16A2/3, M16A4 and M4 Carbine (Army Field Manual)

- Operator's Manual for Rifle, 5.56 mm, M16; Rifle 5.56 mm, M16A1

- Operator's Manual for Rifle, 5.56 mm, M16A2; Rifle 5.56 mm, M16A3; Rifle, 5.56 mm, M16A4; Carbine, 5.56 mm, M4; Carbine, 5.56 mm, M4A1

- Video of 1965 training film on the early XM16E1 variant downloadable for free from www.archive.org The Internet Archive

- M16 in parts (German)

- M16 Assault Rifle Description

|

|||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||